Internal Structure of Optical Fiber

Optical fiber is the backbone of modern communication networks, enabling high-speed data transmission with minimal loss. Understanding its internal structure is essential to appreciate how it functions efficiently in various applications, from telecommunications to medical devices.

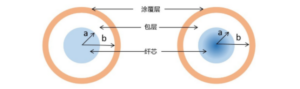

Core

The core is the central part of an optical fiber, where light signals travel. It is typically made of glass or plastic and has a high refractive index to guide light through total internal reflection. The diameter of the core varies depending on the fiber type:

Single-mode fiber (SMF): Core diameter is around 8-10 microns, optimized for long-distance transmission with minimal signal loss.

Multimode fiber (MMF): Core diameter ranges from 50 to 62.5 microns, suitable for short-distance data transmission.

Cladding

Surrounding the core is the cladding, which has a lower refractive index than the core. This refractive index difference ensures that light remains within the core by reflecting off the cladding, a phenomenon known as total internal reflection. The cladding is also made of glass or plastic and plays a crucial role in maintaining signal integrity.

Coating (Buffer Layer)

The coating, also known as the buffer layer, is an additional protective layer applied around the cladding. It is typically made of polymer materials such as acrylate, which provides:

Mechanical protection against bending and environmental damage.

Moisture resistance to prevent degradation of the fiber.

Improved durability during handling and installation.

Strength Members

To enhance durability, optical fibers include strength members, such as aramid yarn (e.g., Kevlar), fiberglass, or steel wires. These materials help protect the fiber from mechanical stress, bending, and stretching, especially in outdoor and harsh environments.

Outer Jacket

The outer jacket is the external protective layer that safeguards the fiber from physical damage, environmental factors, and chemical exposure. The material used for the jacket varies based on the application:

PVC (Polyvinyl Chloride): Common in indoor fiber cables.

LSZH (Low Smoke Zero Halogen): Used in environments where fire safety is a concern.

PE (Polyethylene): Suitable for outdoor applications due to its UV resistance.

In Conclusion

The internal structure of optical fiber is designed to ensure efficient and reliable data transmission. The combination of the core, cladding, coating, strength members, and outer jacket enables optical fibers to deliver high-speed communication with minimal signal loss. As fiber optics technology continues to advance, improvements in these structural components will further enhance performance and expand its applications in various industries.

Explore more: For more information on Internal Structure of Optical Fiber, visit TARLUZ.com or contact our experts for personalized advice.